- “Connector cable colour difference check” already exists in your wishlist

-

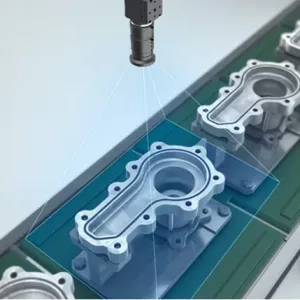

Front/Back differentiation for pressed metal parts

Products can easily be differentiated according to front/back, orientation, shape, and size.

-

Hot melt presence detection

Hot melts and other targets with unstable shapes and application positions can also be detected accurately.

-

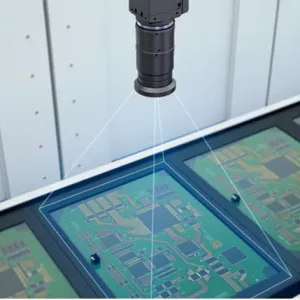

Identification of characters on PCB

Using a high-pixel machine vision allows an entire PCB to be captured within the field of view.

-

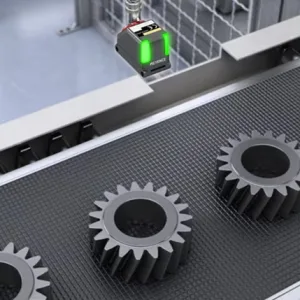

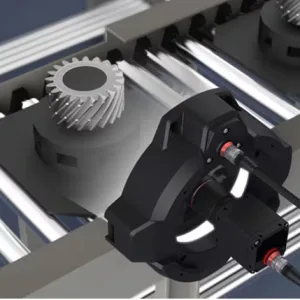

Identifying groove detection in gear assembly processes

The shape and metallic finish of metal gears can make detecting the identifying grooves with a 2D camera unstable, but LumiTrax™ imaging ensures reliable inspection by extracting only the grooves.

-

Inspection for foreign particles in jelly after filling

When inspecting for dirt, hair, and other unacceptable contamination in a packaging process, flexible lighting is needed to detect the NG parts.

-

Inspection of rubber bushings

- Quick pricing from your local KEYENCE sales engineer

- Same-day shipping on most products

- Free on-site demonstrations and testing available

-

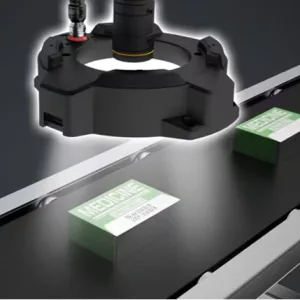

Label alignment inspection

Inspect the labels wrapped around containers for misalignment. In addition to misalignment, peeling labels and other appearance defects can be inspected simultaneously

-

O ring burr inspection

Capturing the entirety of the part with a high-resolution camera enables inspections that can catch even the smallest burrs on O rings.

-

OCR with electronic PCBs

Although marking inspections with conventional systems meant capturing separate images, processing times can be improved by capturing the entire field of view all at once with the high-pixel camera.

-

Packaging seal inspection

The inspection of packet sealing width was unstable due to the influence of patterns, uneven surfaces and glare. The LumiTrax™ function enables inspection based on shape only, by using the information of the uneven surface of the sealed section.

-

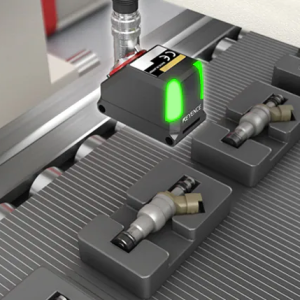

Part mounting confirmation

The presence of parts in multiple locations can be detected with a single unit.

-

Presence inspection for seasoning packets

Using machine vision, check the presence or absence of packets of ingredients and soup in instant noodles. A single controller can control multiple cameras. This improves operability and enables use for parallel production lines.

-

Print inspection of aluminum film

In conventional inspections, the gloss and background colour of the target can cause difficulties in text or marking identification. By using LumiTrax™ mode, it is possible to accurately extract only the uneven surfaces of text and markings, resulting in stable and reliable inspections.

-

Print inspection of medical cartons

In conventional inspections, similar colours between the background and the markings can cause difficulties.

-

Product type differentiation of injectors

With one unit, injectors can be differentiated according to multiple items such as colour and shape differences and component presence.

-

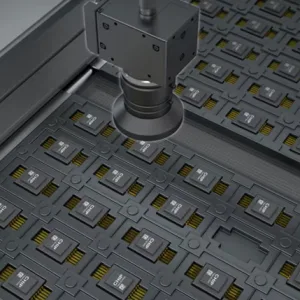

Product type differentiation/2D identification of IC packages

Read the characters/2D codes laser-marked on the surface of IC chips. A single machine vision can recognize both characters, such as part numbers, and 2D codes simultaneously.