-

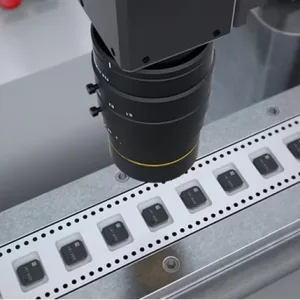

Product type differentiation/2D identification of IC packages

Read the characters/2D codes laser-marked on the surface of IC chips.

-

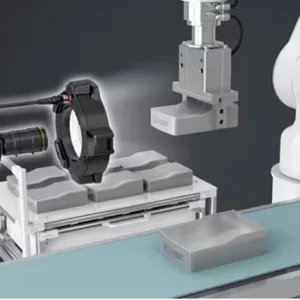

Reading engraved characters on ECU cases

Without LumiTrax™ lighting, reading engraved text is unstable due to variations in the shading of metal surfaces and glare.

-

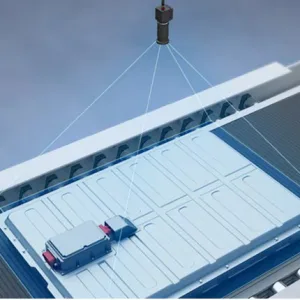

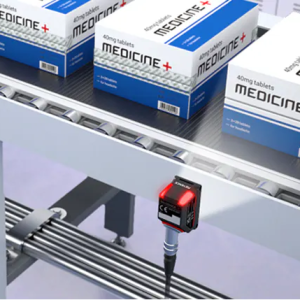

Rechargeable automotive battery label OCR and position inspection

Capturing an image of the entire target all at once makes marking recognition possible for labels in any position.

-

Retaining ring detection

Pattern projection lighting enables stable detection by using 3D height information in combination with 2D colour images. Without height data, detecting proper seating and assembly of low-contrast parts like retaining rings and clips can be challenging and inconsistent.

-

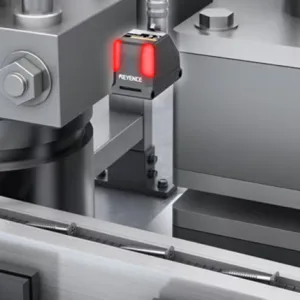

Screw processing presence detection

Even when displacements and diffuse reflections occur, targets are identified with surfaces for accurate detection.

-

Sealing tape presence detection

Translucent targets, mottled patterns, and other such items that reflective sensors have difficulty with are checked as surfaces for stable detection.

-

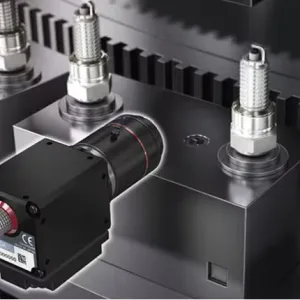

Spark plug dimension inspection

Dimension inspection of complex-shaped targets required the use of multiple measurement tools and calculations.

-

Torque converter assembly inspection

In processes for assembling metal parts, even if the parts are the same colour as the background, inspections unaffected by low contrast and grayscale variations are possible because they are performed with height information obtained from 3D images.

-

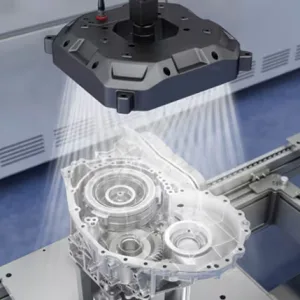

Transmission assembly and sealant inspection

The 3D detection tools enable presence inspections of assembled parts while simultaneously enabling stable inspections of the presence, incompleteness, etc.

-

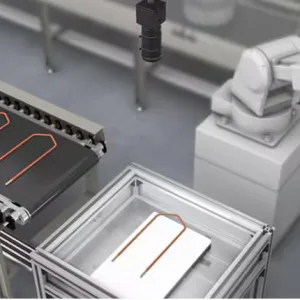

U-pin dimension inspection

Various dimension inspections are necessary after forming flat wires, including measuring the width of the coil ends.

-

Various Part Inspection Inside Tray

*LumiTrax™ lighting creates two images: one to reduce glare, and one to emphasize height features while ignoring colour.

-

Wafer alignment

Whereas conventional systems needed to capture separate images to ensure high resolution, wide-area imaging makes it possible to capture the entire field of view all at once for improved processing times.

-

Wound coil appearance inspection

This is a wound coil appearance inspection example. Such inspections are sometimes unstable due to lighting reflections and variations in the colours with conventional lighting conditions.